LEARN MORE...

SPEAK WITH US

Enquiries: +65 6778.8002

Support: +65 6778.6355

SEND US AN EMAIL

Please use our enquiry form

Monitoring Production

Using Pure's production control, you are able to easily visualise and monitor work orders progressing through their life cycle in many screens including the Job-Manager, Job-Planner and Job-Schedule, where the graphical percentage completion of a task is updated in real time as a blue coloured progress bar.

Production supervisors and Shop-floor line leaders can easily determine which jobs are a priority without needing the planner to constantly update them.

Rush orders are a common occurrence in pretty much every order-driven business, if they are defined as a production plan high priority job, they will be moved to the front of Pure's production plan.

KPI Reporting and Alerts

Numerous printed reports are available showing machine utilisation, efficiency, costing and status, all are updated in real-time and may be printed directly, or downloaded as a pdf or excel spreadsheet.

The global Event Manager promotes a more proactive approach by providing the ability to automatically trigger user-definable alerts or reports when certain conditions occur, quickly drawing attention to issues that require urgent action.

Manufacturing Production Control

Controling production, optimising and continuous improvement becomes effortless once you are able to measure key performance indicators.

Information captured directly from manufacturing work in process updates the database and production plan in real time providing a wealth of information that may be used for production control and kpi reporting.

Many industries including Oil and Gas, Medical Devices and Aerospace require very strict adherence to production control and traceability.

In these industries, adequate controls should be in place to ensure that all processes were all performed as planned, in the correct sequence, and that an audit trail exists detailing the complete product lifecycle history.

With it's inherent procedures, controls and closed-loop feedback, PURE Manufacturing is the ideal platform on which to achieve and maintain your ISO9000 compliance.

Live Status Module

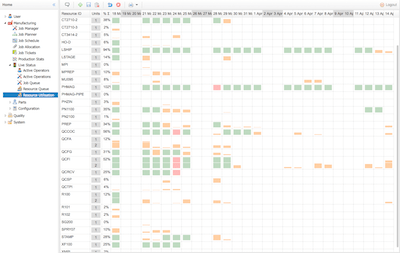

The Live-Status-Module provides several interactive graphical views each showing real time information related to production operators, work centres, work orders and their associated process operations.

The Active-Operators screen shows each production operator, the jobs and operations they are currently working on, and the progress and status of each one.

The Machine Utilisation screen (shown here on the right) provides the graphical loading of each work-center, it is easy to see which resources are optimised and under or over utilised. Green represents 100% utilisation, orange under-utilisation and red shows that the resource is over utilised.

The production plan may be adjusted to smoothen out the machine utilisation, capacity is adjusted by through the Capacity-Override feature to help alleviate bottlenecks.