LEARN MORE...

SPEAK WITH US

Enquiries: +65 6778.8002

Support: +65 6778.6355

SEND US AN EMAIL

Please use our enquiry form

Total Quality Management

PURE Quality is a comprehensive, easy to use, web-based Total Quality Management Solution (T.Q.M / Q.M.S) optimised for the discrete manufacturing sector.

Providing extensive functionality covering Product, Process, Perceived, Progressive, Production and Personnel quality, it effectively promotes continual improvement within the organisation.

It enables the rapid adoption and compliance to industry standards and is designed around the requirements of ISO9001 :2015.

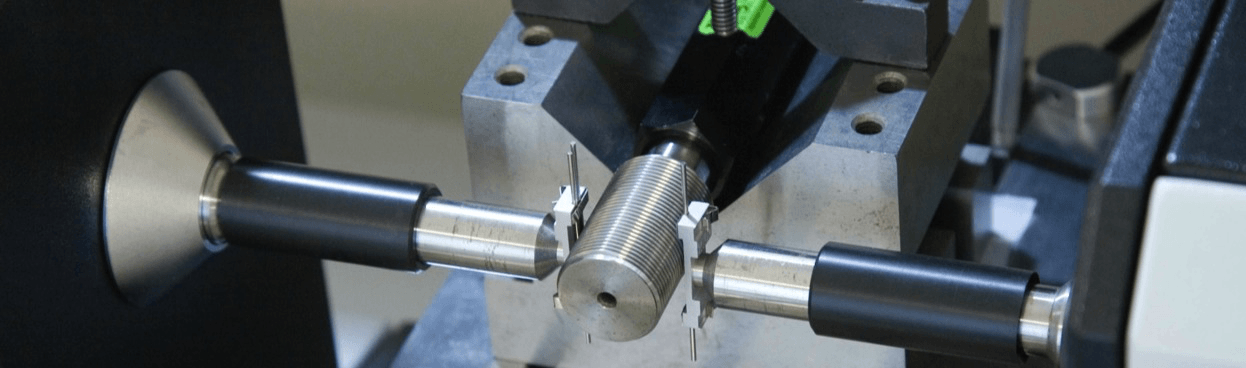

Specifically optimised for the Oil & Gas and Aerospace Engineering industries you can quickly reduce and even completely eliminate antiquated paperwork and the problem of lost or defaced documents which is a reality in many organisations.

Modules include Employee Certification, Gauge Inventory and Calibration, Certificate of Conformance, Product and Gauge Inspection Plans and Test results, Non Conformance, Continual Improvement, Corrective and Preventative Reporting, Customer Feedback and Real-Time graphical analysis of all of the modules.

SPRING Singapore's Enhancing Quality & Standards initiative (CDG-EQS) promotes the adoption of Integrated Management Systems such as PURE Quality, and can provide up to 70% grant funding for Training, Consultancy and Certification services.

Module Summary

Employee Certification

Employee Certification provides the ability to easily maintain a complete record of the training and certification that each production operator has attended and completed.

Gauge Management

Efficiently manage inspection gauges and other assets requiring periodic calibration or maintenance. Tools & gauge inventory control provides traceability, usage and expiry reminders & alerts.

C.O.C Management

The Certificate of Conformance module is used to generate an official printable conformance or CAAS(AW)95 certificate which can accompany any delivered goods certifying compliance to required specifications.

Q.C Plans & Tests

QC Plans are detailed instructions defining all of the measurements and parameters that are required to be performed on either a gauge during calibration, or on a finished product in production.

Continual Improvement

Continual Improvement or C.I, is a consolidated summary of important issues that require extended management monitoring and review.

Non Conformance

Pure N.C.R manages product non-conformances that originate from either a Job Order, a Sales Order or a Purchase Order.

Correct & Prevent

C.P.A.R deals with quality issues that have already occurred, potential issues that have yet to occur, and manages the actions required to resolve them.

Customer Feedback

The C.F module manages direct customer feedback through Emails, Direct Contact, Customer Survey or Customer Perceptions.

Trend Analysis

The Trend Analysis dashboard consolidates historical data gathered from the NCR, CPAR and CF modules presenting the information in graphical and tabular formats.

Improve Quality Productivity

Actions and approvals are performed electronically, upon completion of each of stage and associated documents are automatically routed to the next actioned person.

Users can quickly access their action items through their 'My Documents' folder and receive email notifications and reminders when there are tasks requiring their attention.

The Productivity and Efficiency of the quality department is dramatically improved, allowing quality related tasks to be easily created, managed and actioned in far less time than would be the case with a manual, paper-based system.

Integrated or Stand-Alone

Deployment of PURE Quality can be as a stand-alone solution, or alternatively integrated with PURE Manufacturing for improved productivity and real-time control.

Pure QMS can also be interfaced to other data and E.R.P systems through a powerful 'Restful API' which enables data interchange between Accounting, Sales, Purchasing, Manufacturing & Inventory modules.